- HYPERTERM XDR 300 PRO

- HYPERTERM XDR 300 SOFTWARE

- HYPERTERM XDR 300 ISO

HYPERTERM XDR 300 SOFTWARE

ProNest CAD/CAM software – A single solution for all your profile cutting needs, including plasma, laser, waterjet, and oxyfuel.Using Phoenix software, this CNC improves cut quality and productivity by delivering our expertise to your factory, enabling the best results for your operators.

HYPERTERM XDR 300 PRO

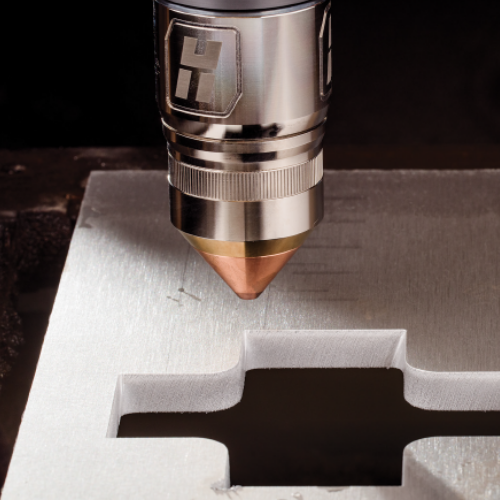

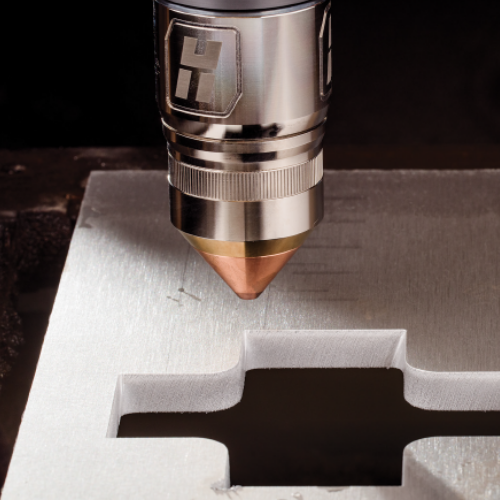

Hypertherm EDGE PRO CNC Control – Designed to be flexible and easy to use, the EDGE Pro delivers reliable performance for improved profitability and application performance. Easy to use interface for fast last minute job adjustments. Up to 80% increase in parts per hour production by minimizing cut to cut cycle time.  Hypertherm AcrGlide torch height control – Superior cutting quality and ideal consumables life with arc voltage sampling and control. The XPR 130 provides high-definition accuracy of 0.1mm, repetition accuracy 0.05mm, low working and initial investment cost, and convenient design for assembly line style production for a wide range of material types and thicknesses up to 1 1./2” Hypertherm XPR 300 or XPR 130 plasma cutting unit – Building on Hypertherm’s industry leading technologies the plasma cutting unit delivers faster cut speeds, higher quality cuts that reduce or eliminate secondary operations and increased consumable life with quicker setup time resulting in reduced operating cost. Designed with the customer experience in mind the EPL plasma cutting machine offers maximum efficiency allowing for custom sizes, special cuts and can be programmed for automated processes. With both oxygen and plasma cutting heads, the EPL offers users high performance and optimal cutting capabilities. Designed to work in the harshest production environments, the EPL plasma cutting machine is equipped with advanced technology and functionality. Top lift eye weight rating 680 kg (1,500 lb.The Ermak EPL high-definition plasma cutting machine is the latest in Ermak’s line of HD plasma cutters. Kit: XPR VWI supply water filter with softnerĮMC emissions classification (CE models only). Preventive maintenance electronics kit for power supplies 380 V or more. Preventive maintenance electronics kit for power supplies 280 V or less. Preventive maintenance filter torch rebuild kit with coolant. Preventive maintenance filter torch rebuild kit without coolant. Consumable start kit: stainless steel/aluminum (with torch). Consumable starter kit: mild steel (with torch).

Hypertherm AcrGlide torch height control – Superior cutting quality and ideal consumables life with arc voltage sampling and control. The XPR 130 provides high-definition accuracy of 0.1mm, repetition accuracy 0.05mm, low working and initial investment cost, and convenient design for assembly line style production for a wide range of material types and thicknesses up to 1 1./2” Hypertherm XPR 300 or XPR 130 plasma cutting unit – Building on Hypertherm’s industry leading technologies the plasma cutting unit delivers faster cut speeds, higher quality cuts that reduce or eliminate secondary operations and increased consumable life with quicker setup time resulting in reduced operating cost. Designed with the customer experience in mind the EPL plasma cutting machine offers maximum efficiency allowing for custom sizes, special cuts and can be programmed for automated processes. With both oxygen and plasma cutting heads, the EPL offers users high performance and optimal cutting capabilities. Designed to work in the harshest production environments, the EPL plasma cutting machine is equipped with advanced technology and functionality. Top lift eye weight rating 680 kg (1,500 lb.The Ermak EPL high-definition plasma cutting machine is the latest in Ermak’s line of HD plasma cutters. Kit: XPR VWI supply water filter with softnerĮMC emissions classification (CE models only). Preventive maintenance electronics kit for power supplies 380 V or more. Preventive maintenance electronics kit for power supplies 280 V or less. Preventive maintenance filter torch rebuild kit with coolant. Preventive maintenance filter torch rebuild kit without coolant. Consumable start kit: stainless steel/aluminum (with torch). Consumable starter kit: mild steel (with torch).  Consumable starter kit: stainless steel/aluminum (without torch). Consumable starter kit: mild steel (without torch). All consoles can be fullyĬontrolled through the CNC for high productivity and ease of use. Successively enhanced cutting capabilities on stainless steel and aluminum. Three gas connect console options offer unmatched mild steel cut quality with each console delivering The most significant advance in mechanized plasma cutting technology redefines what plasma can do. WiFi in the power supply can connect to mobile devices and LAN for multiple system monitoring and service. QuickLock™ electrode for easy consumable replacement. Eas圜onnect™ torch lead and one hand torch-to receptacle connection for fast and easy change-outs.

Consumable starter kit: stainless steel/aluminum (without torch). Consumable starter kit: mild steel (without torch). All consoles can be fullyĬontrolled through the CNC for high productivity and ease of use. Successively enhanced cutting capabilities on stainless steel and aluminum. Three gas connect console options offer unmatched mild steel cut quality with each console delivering The most significant advance in mechanized plasma cutting technology redefines what plasma can do. WiFi in the power supply can connect to mobile devices and LAN for multiple system monitoring and service. QuickLock™ electrode for easy consumable replacement. Eas圜onnect™ torch lead and one hand torch-to receptacle connection for fast and easy change-outs.  Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts. Reduces the impact of catastrophic electrode blowouts which can damage the torch at high current levels. Ramp down error protection significantly increases realized consumable life. Thicker piercing capability than competitive plasma systemsĮngineered system optimization and ease of use. Dramatic improvement in consumable life on mild steel applications. Increased cut speeds on thicker materials. Significantly reduced operating costs than previous generation technology. Optimized productivity and reduced operating costs Superior results on aluminum using Vented Water Injection™ (VWI).

Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts. Reduces the impact of catastrophic electrode blowouts which can damage the torch at high current levels. Ramp down error protection significantly increases realized consumable life. Thicker piercing capability than competitive plasma systemsĮngineered system optimization and ease of use. Dramatic improvement in consumable life on mild steel applications. Increased cut speeds on thicker materials. Significantly reduced operating costs than previous generation technology. Optimized productivity and reduced operating costs Superior results on aluminum using Vented Water Injection™ (VWI). HYPERTERM XDR 300 ISO

Consistent ISO range 2 results on thin mild steel and extended range 3 cut quality on thicker mild steel and stainless steel.The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition™ cutting on mild steel, stainless steel and aluminum. Industry leading cut quality – X-Definition

0 kommentar(er)

0 kommentar(er)